Water Jet Fabrication Tips for Efficient and Precise Cutting?

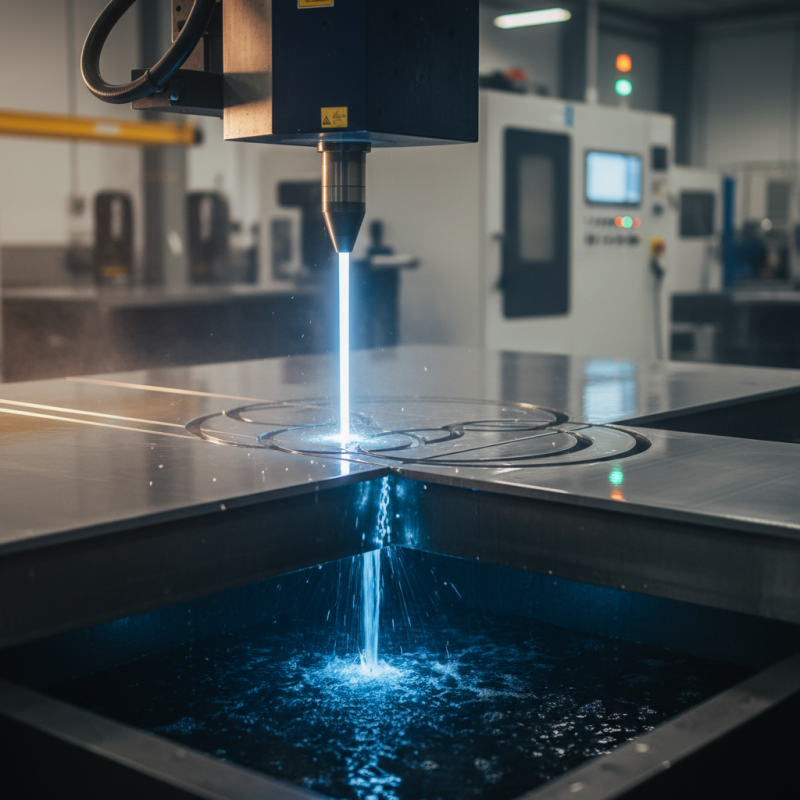

Water jet fabrication has revolutionized the cutting industry. It combines precision with efficiency, making it a popular choice for various materials. This method uses high-pressure water streams mixed with abrasive materials. This technique ensures clean and accurate cuts, essential for complex designs.

However, achieving optimal results requires careful planning and execution. Operators must select the right nozzle and maintain appropriate pressure. They also need to consider material thickness and type. Minor adjustments can make major differences. Mistakes in settings could lead to rough edges or wasted materials.

Understanding the nuances of water jet fabrication is crucial. Each project brings unique challenges. Operators often learn from experiences, reflecting on what worked and what didn’t. Embracing continuous improvement can lead to better outcomes and efficient processes.

Understanding Water Jet Fabrication Technology

Water jet fabrication technology has revolutionized the cutting industry. This method uses high-pressure water mixed with abrasives to cut through various materials. Reports indicate that water jet cutting achieves precision levels of ±0.005 inches. This accuracy caters to industries needing tight tolerances, such as aerospace and automotive sectors. By using water jets, companies can reduce waste and enhance material utilization.

Efficiency is another significant aspect of water jet fabrication. Studies show that this cutting method can deliver up to three times faster results compared to traditional techniques. However, operators must remain vigilant about maintenance. Neglecting equipment can lead to inconsistencies in cutting quality. Proper training is crucial to avoid such pitfalls, as inexperienced users might struggle to achieve desired outcomes.

Water jet technology can cut materials ranging from metal to stone, but not every job benefits equally. Thick materials can lead to prolonged cutting times. Additionally, over-reliance on water jet systems can overlook other viable cutting methods, impacting overall production efficiency. Balancing techniques and understanding each method's strengths can guide a more effective fabrication process.

Key Factors Influencing Cutting Efficiency and Precision

Water jet fabrication is a popular method for cutting various materials. Several factors can influence cutting efficiency and precision. The quality of the water jet stream is essential.

A well-maintained nozzle ensures a consistent flow. This, in turn, leads to cleaner cuts and less material wastage. However, small deviations in water pressure can create rough edges on the final product.

The type of abrasive used also matters significantly. Different materials require specific abrasives for optimal results. For example, garnet is a common choice for its effectiveness. Yet, using the wrong abrasive can lead to excessive wear on the machinery and poor cutting quality.

Operators should regularly check their abrasive supply and adjust as necessary.

Cutting speed is another crucial factor. Faster speeds may seem efficient, but they can sacrifice precision. Slower speeds can improve accuracy but might increase production time.

Finding the right balance is key. Moreover, an operator’s skill level plays a critical role. Even small mistakes in alignment or settings can cause significant issues.

Continuous training and reflection on past projects are vital for honing skills in water jet fabrication.

Best Practices for Material Selection in Water Jet Cutting

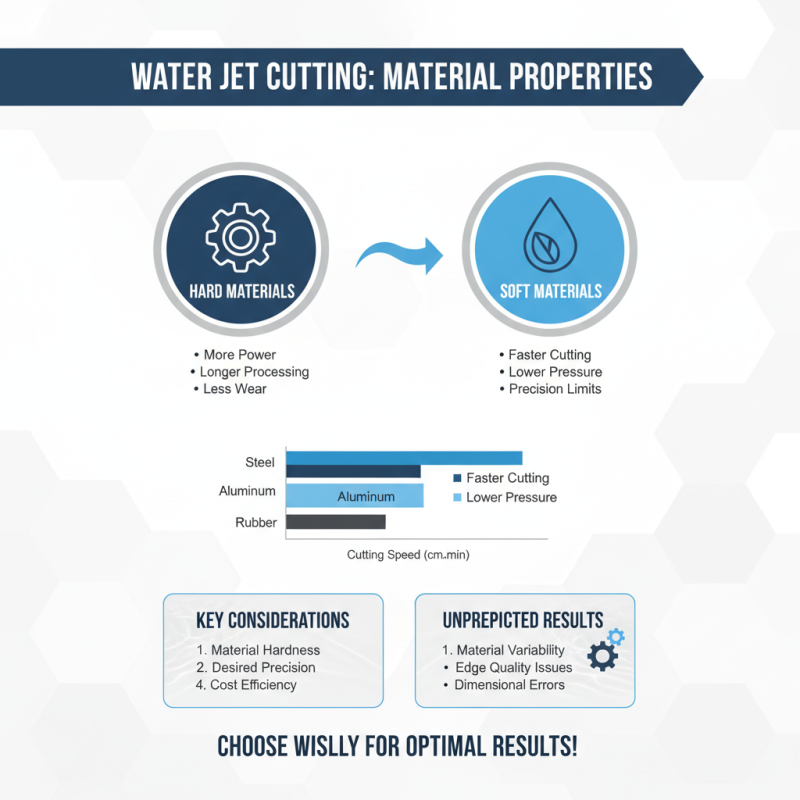

When selecting materials for water jet cutting, it's crucial to consider their properties carefully. Hard materials may require more power and longer processing time. Softer materials can yield faster results but may have limitations in precision. Each material behaves differently under water jet pressure. This variability can lead to unexpected results if not properly addressed.

A common pitfall is choosing a material solely based on cost. While budget constraints matter, performance is key. For instance, using a low-cost metal may lead to rough edges and increased waste. This not only affects the final product but can also result in higher operational costs. It’s worth investing time to research material compatibility with water jet cutting.

Another consideration is thickness. Materials that are overly thick often require multiple passes, which can be time-consuming. Thin materials can be cut quickly, but they may warp under pressure. Finding the right thickness balance is essential for achieving a clean cut. Maintaining a focus on these details can significantly improve the cutting process. The outcome is often more precise and cost-effective in the long run.

Techniques for Optimizing Water Jet Settings and Parameters

When optimizing water jet cutting, adjust the pressure settings carefully. A pressure that is too low leads to poor cutting quality. Conversely, excessive pressure can cause damage to the material. Start with moderate pressure and make small adjustments based on test cuts. Monitoring the results closely is essential.

The abrasive feed rate also plays a crucial role. Using too much abrasive can increase costs and waste material. A slower feed rate can allow for a smoother finish, yet it might slow down production time. Experimentation is key to finding the right balance. Abandoning old settings might be necessary for new materials or designs.

Pay attention to the cutting speed as well. If it's too fast, cuts may be rough and uneven. Slow down to achieve precision, especially on intricate designs. Additionally, the water temperature and nozzle size should not be overlooked.

Maintaining an optimal water temperature can improve cutting efficiency while the right nozzle size dictates the accuracy of the stream. These parameters require continuous adjustment and reflection for better outcomes.

Maintenance Tips for Consistent Performance in Water Jet Machines

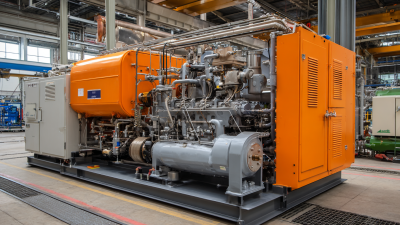

Maintaining water jet machines is crucial for their efficiency. Regular inspections can prevent unexpected downtimes. Check the components frequently. Look for wear and tear in the nozzles and abrasive flow systems. If you notice any inconsistencies, address them immediately. Small issues can escalate quickly during cutting operations.

Keep the water quality in mind. Impurities can affect the cutting precision. Use filtered water to minimize debris. It’s a simple step that goes a long way. Remember to clean the filtration system regularly. Sometimes, it’s easy to overlook this. A neglected filter can lead to poor performance.

Monitor the pressure settings closely. Inconsistent pressures may cause irregular cuts. Test the machine's performance regularly. Adjust as necessary to maintain accuracy. Keep a log of the machine’s performance. This practice can highlight trends over time. Reflect on what might be improved in your setup. Continuous learning is key to effective water jet fabrication.

Water Jet Fabrication Efficiency Analysis

Related Posts

-

The Ultimate Guide to Understanding How a Water Jet Head Transforms Industrial Cutting

-

Maximize Precision and Efficiency with Local Water Jet Cutting: The Future of Material Processing

-

The Future of Cutting Technologies Exploring the Benefits of Water Jet Abrasive Systems

-

Exploring the Benefits of Water Jet Cutting for Precision Stainless Steel Fabrication

-

Understanding the Benefits of Water Jet Cutting Machines in Modern Manufacturing

-

Top 10 Waterjet Cutting Parts for Precision Engineering Applications