2026 Best Waterjet Cutting Aluminum Techniques for Precision Manufacturing?

In the realm of precision manufacturing, waterjet cutting aluminum is gaining traction for its unique capabilities. Experts like Dr. Emily Carter, a recognized authority in this field, emphasize its importance. “Waterjet cutting aluminum offers unmatched precision and versatility,” she states. This method allows for intricate designs without compromising material integrity.

The allure of waterjet cutting lies in its ability to handle various aluminum grades. It produces clean edges and intricate shapes, which are essential in industries like aerospace and automotive. Yet, despite its many advantages, challenges remain. Operators must ensure proper equipment calibration to achieve ideal results.

Some machinery struggles with thick aluminum sheets, impacting efficiency. Additionally, getting the right water pressure is crucial. A balance must be struck between power and precision. As the industry advances, learning from imperfections will drive innovation in waterjet cutting aluminum techniques. Embracing these challenges can lead to groundbreaking methods in precision manufacturing.

Overview of Waterjet Cutting Technology in Aluminum Manufacturing

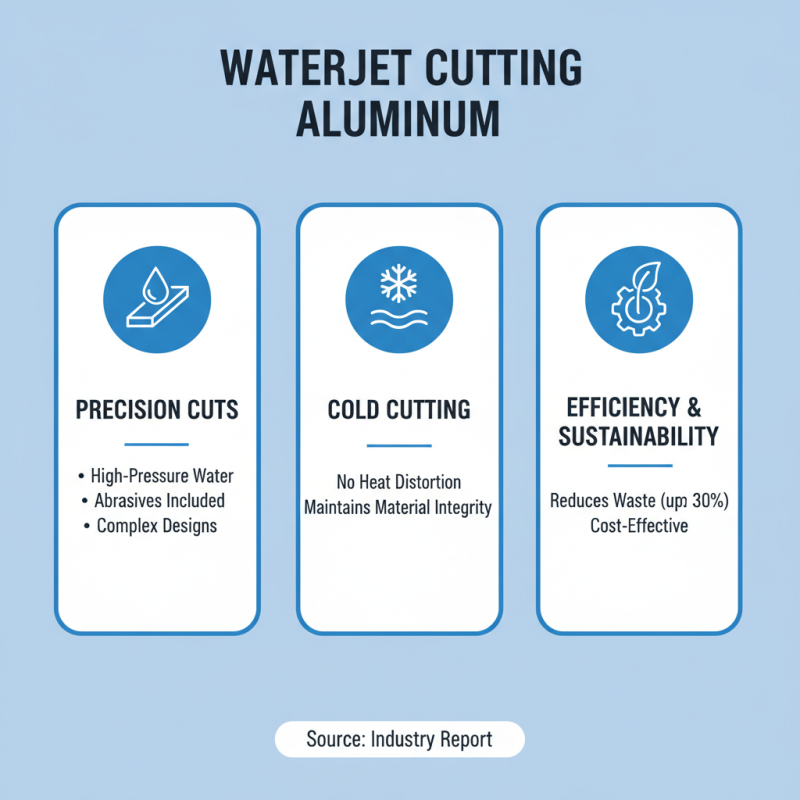

Waterjet cutting technology has emerged as a powerful method for aluminum manufacturing. It utilizes high-pressure water mixed with abrasives to create precise cuts. This technique is notable for its ability to cut complex designs without generating heat, which can distort the material. According to a recent industry report, waterjet cutting reduces material waste by up to 30%, making it an efficient choice for manufacturers.

Precision is crucial in modern manufacturing. Waterjet cutting offers accuracy within ±0.005 inches, surpassing many traditional methods. It achieves this precision while maintaining a smooth edge finish. Despite its advantages, the setup cost can be high, and operators require training. Inadequate training may lead to miscalculations or inefficiencies.

As manufacturers strive for sustainability, waterjet cutting aligns well with eco-friendly practices. The process uses no harmful chemicals, making it safer for environments. However, companies need to consider maintenance and the cost of abrasives. Balancing these factors is essential. Understanding the technology's limitations helps manufacturers make informed choices about processes in precision aluminum cutting.

Key Advantages of Using Waterjet Cutting for Aluminum Projects

Waterjet cutting is a game changer for aluminum projects. This technique uses high-pressure water mixed with abrasives to slice through metal. The result is clean, precise cuts that reduce the need for secondary processes. When working with aluminum, this precision is crucial. It minimizes the risk of warping, ensuring the final product meets strict specifications.

One significant advantage of waterjet cutting is its versatility. It can handle complex shapes that traditional methods struggle with. Intricate designs become feasible without sacrificing quality. However, it's essential to consider the limitations. The process can be slow for thicker materials, affecting productivity. Yet, for detailed work, the speed of setup can outweigh this drawback.

Cost-effectiveness is another key benefit. Though initial setup may seem high, waterjet cutting reduces wastage. This efficiency translates into savings in the long run. It's important to reflect on these aspects. While waterjet cutting is not perfect, its advantages in aluminum projects often make it the ideal choice in many situations.

Essential Techniques for Precision Waterjet Cutting of Aluminum

Waterjet cutting is an innovative technique for machining aluminum. This method uses high-pressure water mixed with abrasive materials to cut through metal with precision. One crucial aspect is selecting the correct nozzle size. A smaller nozzle creates a finer cut, while a larger one enhances speed. However, this requires careful calibration. Often, operators neglect this step, leading to uneven cuts.

Another essential technique involves controlling the speed of the cutting head. A slower speed may produce a cleaner edge but can impact production time. Balancing these factors is vital. Many manufacturers overlook this detail and only realize the importance when facing quality issues.

Additionally, maintaining the water pressure is crucial. Inconsistent pressure can lead to variations in cutting quality. Regular checks on the water filtration system can prevent clogs and maintain optimal performance. Ignoring this can result in downtime and increased costs. Good practices in these areas ensure precise waterjet cutting of aluminum, but there's always room for improvement in efficiency and accuracy.

2026 Best Waterjet Cutting Aluminum Techniques for Precision Manufacturing

| Technique | Description | Benefits | Applications |

|---|---|---|---|

| Abrasive Waterjet Cutting | A method using a high-pressure jet of water mixed with abrasive particles. | High precision, minimal heat affected zone. | Aerospace components, automotive parts. |

| Pure Water Cutting | Utilizes only water under high pressure for cutting softer materials. | Cleaner cuts, no abrasives needed. | Food packaging, textile cutting. |

| Dynamic Waterjet Cutting | Adjusts the cutting head dynamics based on material thickness. | Enhanced edge quality and longer consumable life. | Complex shapes in aluminum and composites. |

| Multi-Axis Waterjet Cutting | Involves cutting on multiple axes for intricate designs. | Ability to create complex geometries with precision. | Custom part manufacturing, artistic designs. |

| Waterjet Technology Integration | Combining waterjet with CNC machining for increased efficiency. | Reduces operational time and cost. | Large scale manufacturing and prototyping. |

Quality Control Measures in Waterjet Aluminum Cutting Processes

In waterjet cutting aluminum processes, quality control is crucial. The precision of the cuts directly affects the final product. Regular inspections help detect any inconsistencies early. This minimizes costly rework and ensures optimal outcomes.

Tips: Always check for nozzle wear. A worn nozzle can affect the cut quality and precision. Keep a log of any deviations in cutting speed and pressure. It can reveal patterns needing attention.

Another pivotal aspect is the alignment of the waterjet system. Misalignment can cause uneven cuts. Operators should perform regular calibrations. This step is often overlooked but vital for maintaining accuracy. Addressing this can save time and materials.

Tips: Consider implementing a maintenance schedule. Routine checks show if the system operates correctly. Don't wait for problems to arise. Being proactive is better than reacting after an issue occurs.

Future Trends in Waterjet Cutting Technology for Aluminum Applications

Waterjet cutting technology is evolving rapidly, especially for aluminum applications. According to a recent industry report, the market for waterjet cutting is projected to reach $1.5 billion by 2026. This significant growth indicates a rising demand for precision and efficiency in manufacturing processes. As manufacturers seek to optimize their workflows, adopting the latest cutting techniques becomes increasingly important.

One notable trend is the integration of automation and advanced software systems. These advancements aim to enhance cutting accuracy and reduce operational costs. For instance, new algorithms are being developed to improve cutting paths and minimize material waste. However, despite these innovations, some users report challenges in maintaining consistent edge quality. This inconsistency can lead to increased rework and downtime.

Moreover, the use of ultra-high-pressure waterjet systems is on the rise. These systems increase cutting speed and precision, which can result in a smoother finish on aluminum pieces. Data shows that high-pressure waterjet cutters can cut aluminum up to three times faster than traditional methods. Nonetheless, operators may face a steep learning curve when transitioning to these advanced systems. Adequate training is essential, yet often overlooked. This imbalance between technology adoption and operator readiness needs addressing to ensure the full potential of modern waterjet cutting techniques is realized.

Related Posts

-

Why Choose Waterjet Cutting Services in Seattle for Your Precision Needs?

-

Top Tips for Maintaining Waterjet Cutting Parts for Optimal Performance

-

Why is Waterjet Cutting the Best Choice for Precision Manufacturing

-

Understanding the Benefits of Jet Cut Technology in Modern Manufacturing

-

The Future of Precision Manufacturing with Waterjet Cutting Technology in Utah

-

Top 10 Waterjet Cutting Parts for Precision Engineering Applications