Best Water Jet Cutting Machines for Precision Cutting?

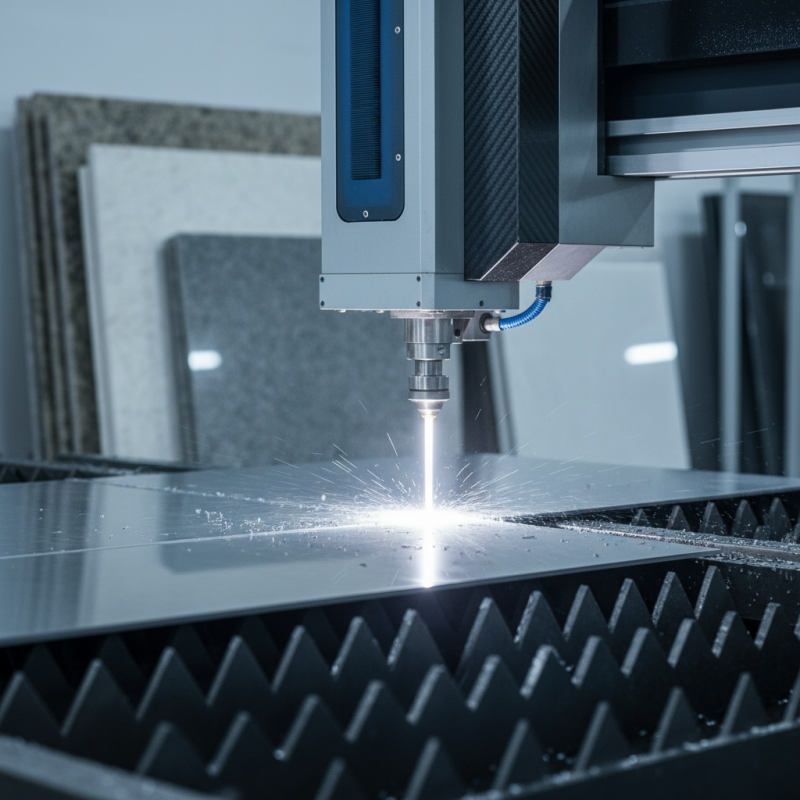

In the world of manufacturing, precision is crucial. The **water jet cutting machine** has emerged as a reliable tool for achieving intricate cuts in various materials. These machines utilize high-pressure water streams, often mixed with abrasives, to slice through tough surfaces like metal, glass, and stone. The fine control they offer can result in stunning designs and accurate dimensions.

However, choosing the best water jet cutting machine can be overwhelming. Many models promise efficiency and precision, but not all deliver. A few may fall short in terms of reliability or maintenance costs. It’s essential to dive deep into specifications, user reviews, and brand reputation before making a decision.

Buying a water jet cutting machine requires careful consideration of your specific needs. Think about the types of materials you work with most. Also, reflect on the volume of production you expect. Remember, even the best machines can have drawbacks. Each model may excel in one area while lagging in another. Therefore, understanding both the strengths and weaknesses of options is vital.

Best Water Jet Cutting Machines: An Overview of Key Features

Water jet cutting machines are essential for precision cutting across various industries. These machines utilize high-pressure water jets to cut materials with incredible accuracy. Key features to consider include pressure levels, nozzle design, and cutting speed. A machine that generates higher pressure can cut through thicker materials. However, managing this power requires expertise in settings and calibration.

Nozzle design plays a crucial role in the cutting process. Different materials demand different nozzle types. The wrong choice can lead to unsatisfactory results or wasted resources. Additionally, the cutting speed is vital; too fast can compromise quality, while too slow may reduce efficiency. Operators must strike a balance, which can be challenging at times.

Customization options also matter. The ability to adapt the machine for specific tasks is a game changer. However, not all machines offer this flexibility, leading to potential constraints. Operators may find themselves frustrated when the machine falls short of expectations. Precision cutting is not just about the machine but also about the operator’s skill and understanding of the process. Mastery requires time, and it's a journey of continual learning.

Types of Water Jet Cutting Machines: Abrasive vs. Pure Water Jets

Water jet cutting machines are powerful tools used in various industries. They can perform precise cuts on different materials, ranging from metal to glass. The two main types of water jet cutting machines are abrasive and pure water jets. Each type has unique attributes that cater to specific needs.

Abrasive water jets incorporate an abrasive material, such as garnet, mixed with high-pressure water. This combination allows for cutting through tough materials like steel and titanium. According to industry reports, abrasive jets can reach pressures of up to 90,000 psi. This makes them effective for heavy-duty applications. However, the use of abrasives can result in higher operating costs and increased wear on the components.

On the other hand, pure water jets use only high-pressure water for cutting softer materials, like foam or food. They operate at lower pressures, typically around 30,000 psi. This method generates minimal heat and is ideal for materials sensitive to temperature changes. Due to their simplicity, pure water jets can be less expensive to maintain. Yet, they are limited in their cutting capabilities. They struggle with tougher materials, requiring careful material selection.

Choosing the right type depends on the specific application and materials involved. As with any technology, it’s essential to evaluate the strengths and weaknesses of abrasive versus pure water jets.

Top Brands in Water Jet Cutting Machines: Market Share and Innovations

Water jet cutting technology continues to evolve, driven by innovative approaches and market demands. Several key players dominate the landscape, showcasing their unique features and capabilities. These machines utilize high-pressure water to cut materials with unparalleled precision. This method is ideal for a variety of industries, from aerospace to automotive.

Market trends indicate a growing interest in eco-friendly solutions. Many brands focus on reducing waste and energy consumption. This shift addresses both environmental concerns and operational efficiency. Innovations in control systems enhance user experience, but not all options are intuitive. Some users find the learning curve steep, making initial operations a challenge.

The landscape of water jet cutting machines is competitive and diverse. Emerging technologies promise to enhance accuracy and speed. However, some brands still lag in customer support and maintenance services. Users often express frustration over these inconsistencies. It's essential for buyers to evaluate reliability and innovation comprehensively before making a decision.

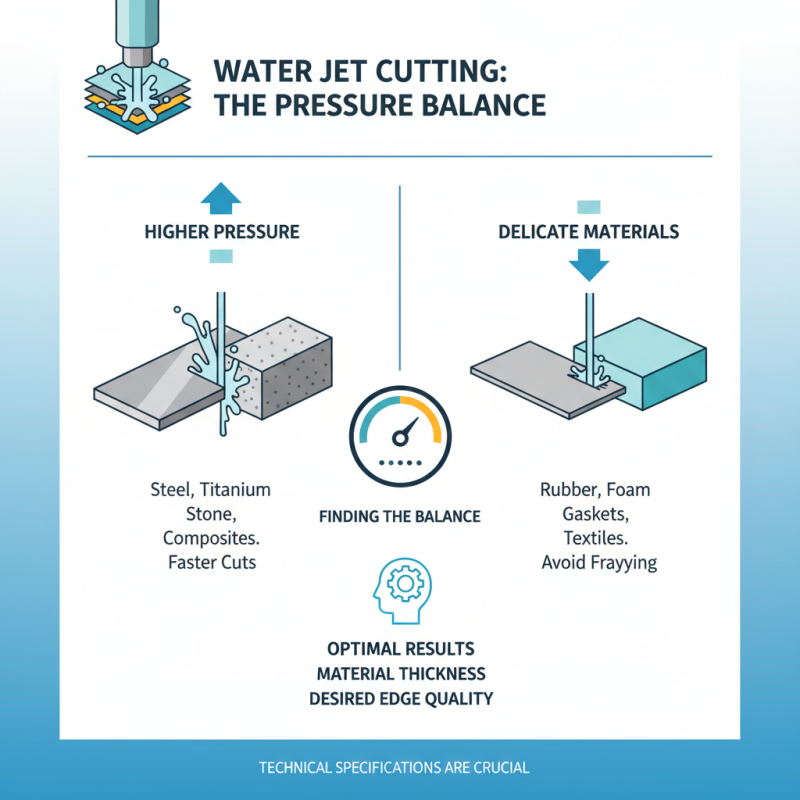

Technical Specifications: Understanding Pressure, Nozzle Size, and More

When it comes to water jet cutting, understanding the technical specifications is crucial. Pressure plays a significant role. Higher pressure can cut through tougher materials with ease. However, not all materials require the same pressure. Sometimes, using too much can lead to unwanted fraying on delicate surfaces. It’s about finding balance.

Nozzle size also affects precision and cut quality. A smaller nozzle creates a narrower stream, ideal for intricate designs. Meanwhile, a larger nozzle works better for broader cuts. Yet, using the wrong size can produce imprecise edges. It's a common area where many operators need improvement. Experimentation is key.

Another thing to consider is the abrasive material used. The right abrasive can enhance cutting efficiency. However, some may not provide the desired finish. This can lead to rework and wasted resources. Understanding these nuances is essential for achieving the best results in water jet cutting. Each parameter requires attention and sometimes a bit of trial and error.

Applications of Water Jet Cutting Machines Across Industries: Case Studies

Water jet cutting machines have transformed many industries. Their precision and versatility make them popular for various applications. For example, in the aerospace sector, these machines cut complex shapes from materials like aluminum and titanium. The ability to maintain tight tolerances is crucial in this field. The result? Improved performance and reduced material waste.

In the stone industry, water jets are used to create intricately designed countertops and tiles. The high-pressure water stream can easily navigate curves that would be challenging with traditional cutting methods. Craftsmanship is not lost; every piece tells a story of artistry and precision. However, labor costs can be high, and operators must be skilled.

Tips: Ensure safety protocols are in place. Always wear protective gear. Experiment with different materials to expand capabilities. Regular maintenance of the machines is essential as it helps to avoid breakdowns that can halt production. Make adjustments based on feedback; it’s a continuous learning process.

Water jet cutting machines serve many applications, from metal art to automotive parts. However, some challenges remain. Operators may struggle with setup time and material limitations. Each industry has unique demands that require constant adaptation and learning.

Related Posts

-

Maximize Precision and Efficiency with Local Water Jet Cutting: The Future of Material Processing

-

Exploring the Benefits of Water Jet Cutting for Precision Stainless Steel Fabrication

-

Understanding the Benefits of Water Jet Cutting Machines in Modern Manufacturing

-

Unlocking Precision: How Water Jet Cutting Systems Revolutionize Metal Fabrication with 0.005-Inch Accuracy

-

How to Use Water Jet Cutting for Steel: A Complete Guide

-

Top Benefits of Local Water Jet Cutting for Precision Manufacturing?