Understanding the Benefits of Water Jet Cutting Machines in Modern Manufacturing

In the realm of modern manufacturing, the adoption of advanced technologies is pivotal for enhancing precision, efficiency, and sustainability. One such technology that has gained significant traction is the water jet cutting machine. According to a report by MarketsandMarkets, the global water jet cutting market is expected to grow from USD 2.54 billion in 2020 to USD 4.02 billion by 2025, reflecting a CAGR of 9.6%. This growth is largely driven by the increasing demand for precision machining in various industries, including aerospace, automotive, and construction. Water jet cutting machines offer unparalleled versatility, capable of processing a wide range of materials—from metals and glass to stone and plastics—with minimal kerf and heat-affected zones. By leveraging the unique attributes of water jet technology, manufacturers can achieve intricate cuts and complex geometries, ultimately streamlining production processes and reducing waste. Understanding the benefits of water jet cutting machines is essential for manufacturers aiming to stay competitive in this rapidly evolving market.

Advantages of Water Jet Cutting Technology Over Traditional Methods

Water jet cutting technology has revolutionized modern manufacturing by offering a range of advantages over traditional cutting methods. One of the key benefits is its ability to cut a wide variety of materials, including metals, glass, and ceramics, without generating heat-affected zones. According to a study by the WaterJet Technology Association, this method reduces material distortion and retains the integrity of the material, making it ideal for precision applications. Furthermore, water jet cutting operates with minimal waste, making it an environmentally friendly option for manufacturers striving for sustainability.

Tips: To maximize efficiency with water jet cutting, ensure regular maintenance of your machine to prevent downtime. Additionally, optimizing your cutting parameters can significantly enhance material yield and reduce operational costs.

Another significant advantage of water jet cutting is its capacity for intricate designs and high accuracy. Unlike traditional cutting methods, which may struggle with complex geometries, water jet machines can achieve tolerances as tight as ±0.005 inches. A report from Global Industry Analysts highlights that the growth of the water jet cutting market is driven by increasing demand for customization in industries such as aerospace and automotive. By leveraging this technology, manufacturers can remain competitive and agile in an ever-evolving marketplace.

Tips: Consider investing in advanced software for water jet cutting that can streamline design and reduce programming time, boosting your overall productivity.

Benefits of Water Jet Cutting Machines in Modern Manufacturing

Enhancing Precision and Versatility in Material Cutting Processes

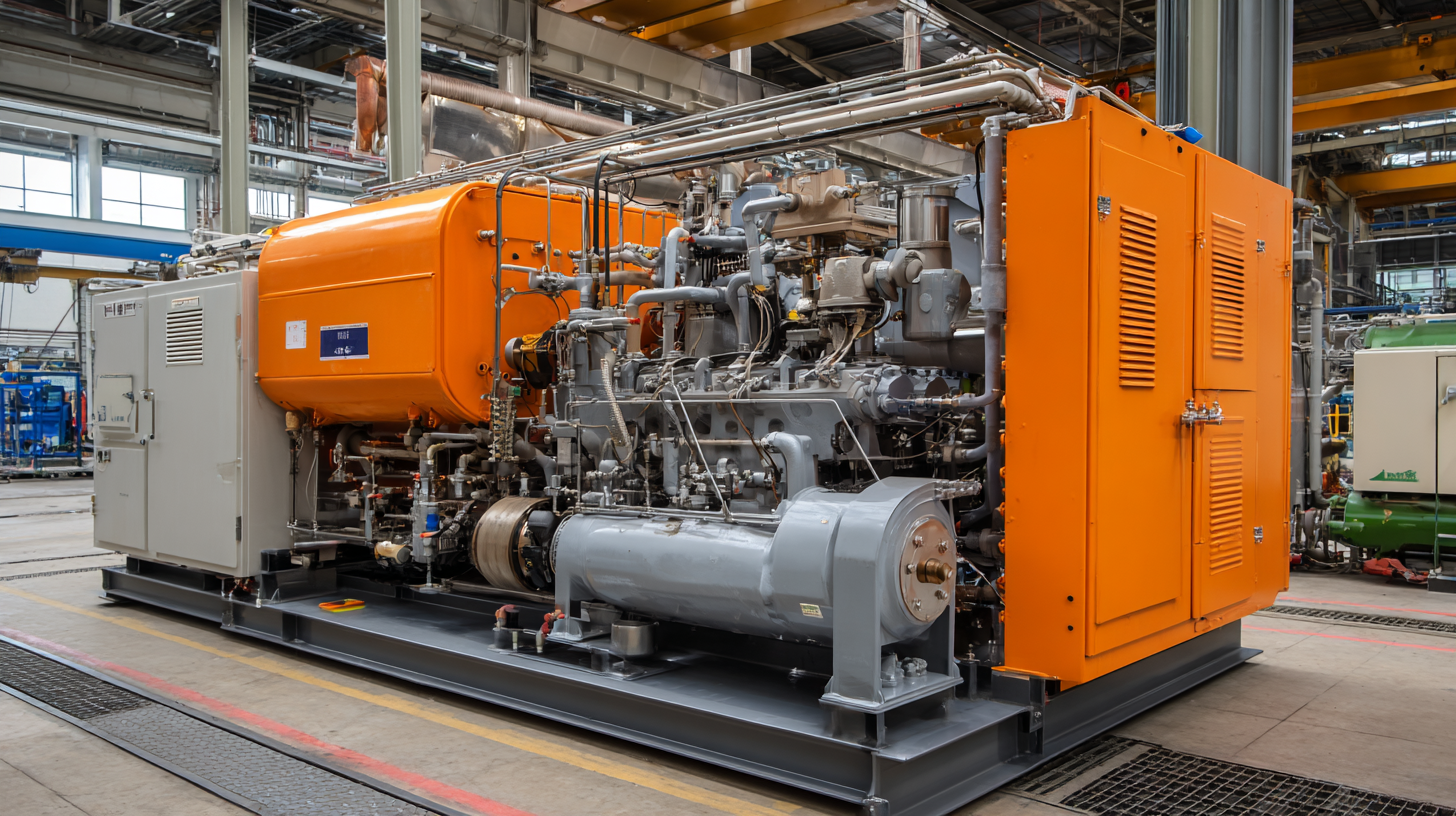

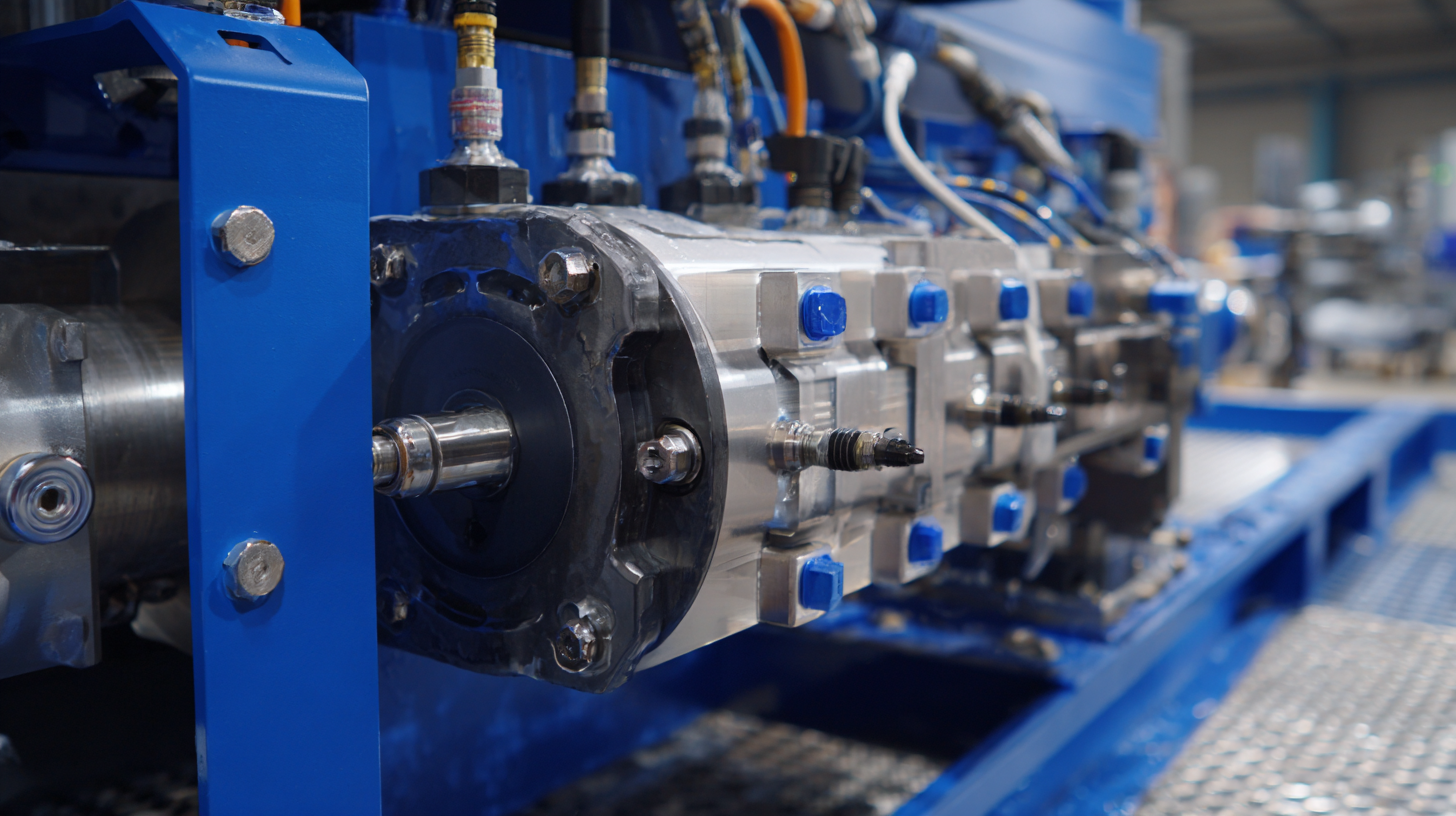

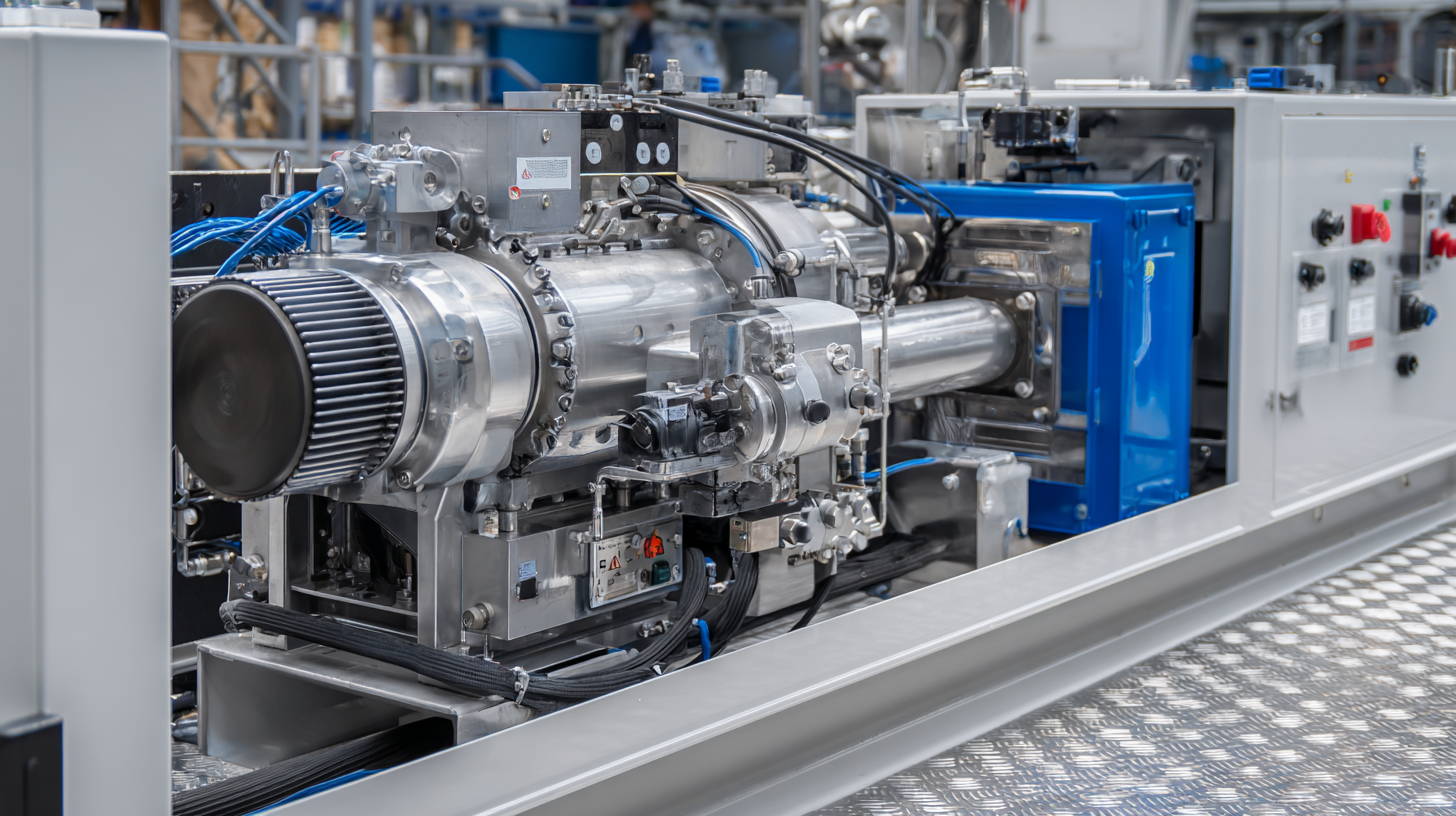

Water jet cutting machines have revolutionized the manufacturing landscape by providing unmatched precision in material cutting processes. Unlike traditional cutting methods, which can produce significant heat and lead to material distortion, water jet cutting utilizes a high-pressure stream of water mixed with abrasive particles. This innovative technique allows for intricate designs and complex shapes to be achieved with minimal kerf width, ensuring that every cut is exact and clean. The ability to cut a wide range of materials, from metals to glass and composites, emphasizes the versatility of water jet technology, making it an invaluable asset in various industries.

Moreover, the versatility of water jet cutting machines enhances their utility across different applications. They can adapt to various thicknesses and types of materials without the need for specialized tooling or frequent setup changes, significantly reducing downtime. Additionally, water jet cutting is an eco-friendly process, as it produces minimal waste and does not generate harmful fumes, unlike laser cutting or plasma cutting methods. This not only meets the growing demand for sustainable manufacturing practices but also appeals to businesses striving for efficiency and cost-effectiveness. Through these advantages, water jet cutting machines continue to play a pivotal role in advancing modern manufacturing capabilities.

Cost-Effectiveness and Sustainability of Water Jet Cutting Machines

Water jet cutting machines have emerged as a vital tool in modern manufacturing, primarily due to their cost-effectiveness and sustainability. According to a report by MarketsandMarkets, the global water jet cutting machine market is projected to reach $2.95 billion by 2025, growing at a CAGR of 5.4%. This growth is driven largely by the machines' ability to reduce operational costs. Water jet cutting utilizes high-pressure water mixed with abrasive materials, producing minimal waste compared to traditional cutting methods, thus lowering material costs and minimizing disposal fees.

Moreover, the sustainability aspect of water jet cutting cannot be overlooked. The process generates no toxic fumes or hazardous waste, making it environmentally friendly. A study published in the Journal of Cleaner Production indicates that water jet cutting can reduce energy consumption by up to 30% compared to laser cutting methods. Furthermore, the ability to cut materials without altering their inherent properties or generating heat ensures that manufacturers can maintain product quality while adhering to eco-friendly practices. As industries move towards sustainable manufacturing solutions, water jet cutting machines stand out as a viable option that aligns with cost-saving objectives and environmental responsibilities.

Applications of Water Jet Cutting Across Various Industries

Water jet cutting machines have revolutionized various industries, showcasing their versatility through a multitude of applications. From aerospace to automotive manufacturing, the ability to cut materials with precision without the introduction of heat has made water jet cutting a preferred method. According to a report from Research and Markets, the global water jet cutting machine market is projected to grow at a CAGR of 6.5% from 2021 to 2026, indicating a robust demand across sectors.

In the construction industry, for example, water jet cutting is employed to slice through tough materials like stone, glass, and metals, enabling intricate designs that were once impossible with traditional cutting methods.

The mining sector has also benefited, utilizing water jets for rock excavation, which significantly reduces vibrations and minimizes environmental disruption. Furthermore, the food industry has begun adopting water jet cutting technology for food processing, allowing for contamination-free cuts and preserving the integrity of food products. As per a survey by the International Water Jet Technology Association, around 30% of manufacturing companies are now incorporating water jet cutting into their processes, highlighting its growing significance across diverse fields.

Future Trends and Innovations in Water Jet Cutting Technologies

As water jet cutting technologies continue to evolve, numerous future trends and innovations are shaping their application in modern manufacturing. One significant trend is the integration of artificial intelligence (AI) and machine learning, which enhances the precision and efficiency of cutting processes. By analyzing data in real-time, AI-driven systems can optimize cutting parameters, reducing material waste and maximizing productivity. This development not only improves the quality of cuts but also allows for better adaptability to various materials and thicknesses.

Another promising innovation is the advancement of ultra-high-pressure pumps, which significantly increase the cutting capabilities of water jet machines. These pumps not only enhance the speed and accuracy of the cutting process but also open new avenues for processing a wider range of materials, including composites and ceramics. Additionally, the introduction of eco-friendly abrasives and water recycling systems addresses environmental concerns, making water jet cutting a sustainable option in manufacturing. As these technologies continue to advance, the potential for increased customization and flexibility in production processes will redefine the landscape of modern manufacturing.

Understanding the Benefits of Water Jet Cutting Machines in Modern Manufacturing

| Feature | Description | Benefits | Future Trends |

|---|---|---|---|

| Precision Cutting | Water jet cutting machines use concentrated water streams to cut materials with high accuracy. | Minimizes material wastage and reduces need for secondary processes. | Integration with AI for predictive maintenance and improved accuracy. |

| Versatility | Can cut through a wide range of materials including metal, glass, and tile. | Allows manufacturers to work on diverse projects without changing equipment. | Development of multi-material cutting capabilities. |

| Environmentally Friendly | Uses water as a cutting medium, reducing toxic waste compared to traditional methods. | Supports sustainable manufacturing practices. | Advancements in recycling and reusability of water used in the process. |

| Cost-Effective | Reduces costs associated with tooling and processing. | Lower operational costs lead to higher profit margins. | Increased automation and efficiency through advanced technologies. |

| Safety | Minimizes risk of heat-affected zones and splintering. | Enhances workplace safety by reducing hazards associated with extreme temperatures. | Innovations in machine design for improved operator safety. |

Related Posts

-

Maximize Precision and Efficiency with Local Water Jet Cutting: The Future of Material Processing

-

Exploring the Benefits of Water Jet Cutting for Precision Stainless Steel Fabrication

-

The Future of Precision Manufacturing with Waterjet Cutting Technology in Utah

-

The Future of Cutting Technologies Exploring the Benefits of Water Jet Abrasive Systems

-

The Ultimate Guide to Choosing the Right Disk Mower for Your Lawn Care Needs